AI in Fashion: Redefining Creativity, Sustainability, and Shopping Experiences

February 28, 2025 | News | No Comments

The Future of Fashion: How Artificial Intelligence is Revolutionizing the Industry

The fashion industry is undergoing a massive transformation, and at the heart of this change is Artificial Intelligence. From design to production, AI is reshaping how fashion brands operate, making processes faster, more efficient, and incredibly innovative.

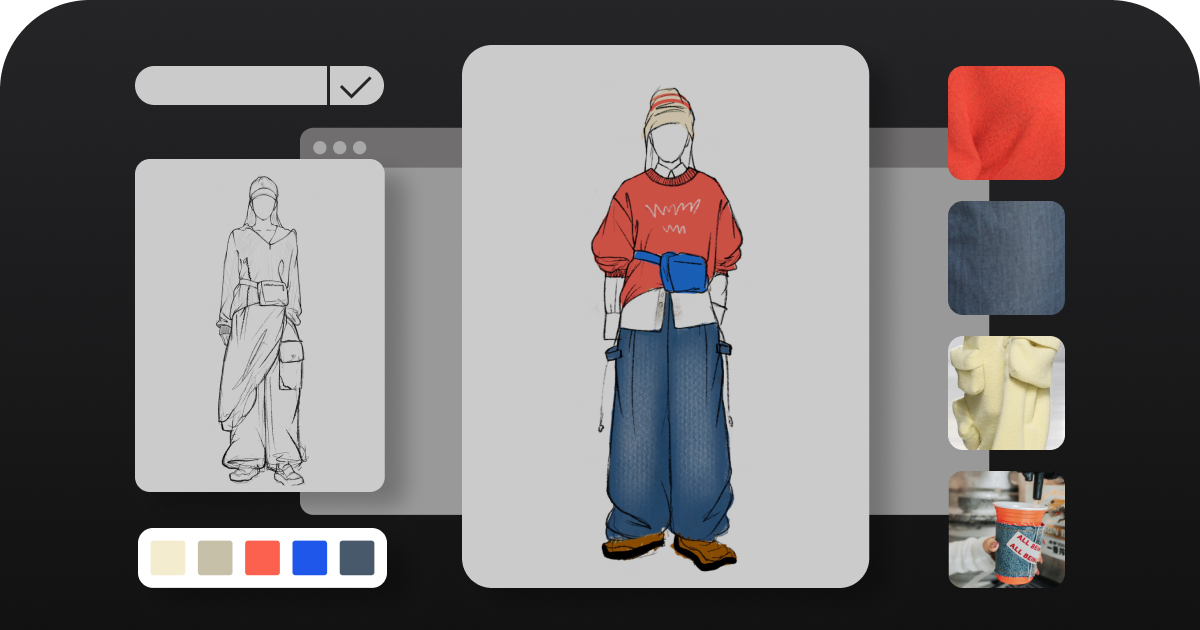

AI in Fashion Design

Gone are the days when fashion design was solely reliant on human creativity. Today, Artificial Intelligence tools are enabling designers to create stunning, trend-driven designs in a fraction of the time. AI algorithms analyze vast amounts of data, including consumer preferences, social media trends, and historical sales data, to predict what styles will resonate with audiences. This not only reduces the risk of producing unpopular designs but also allows brands to stay ahead of the curve.

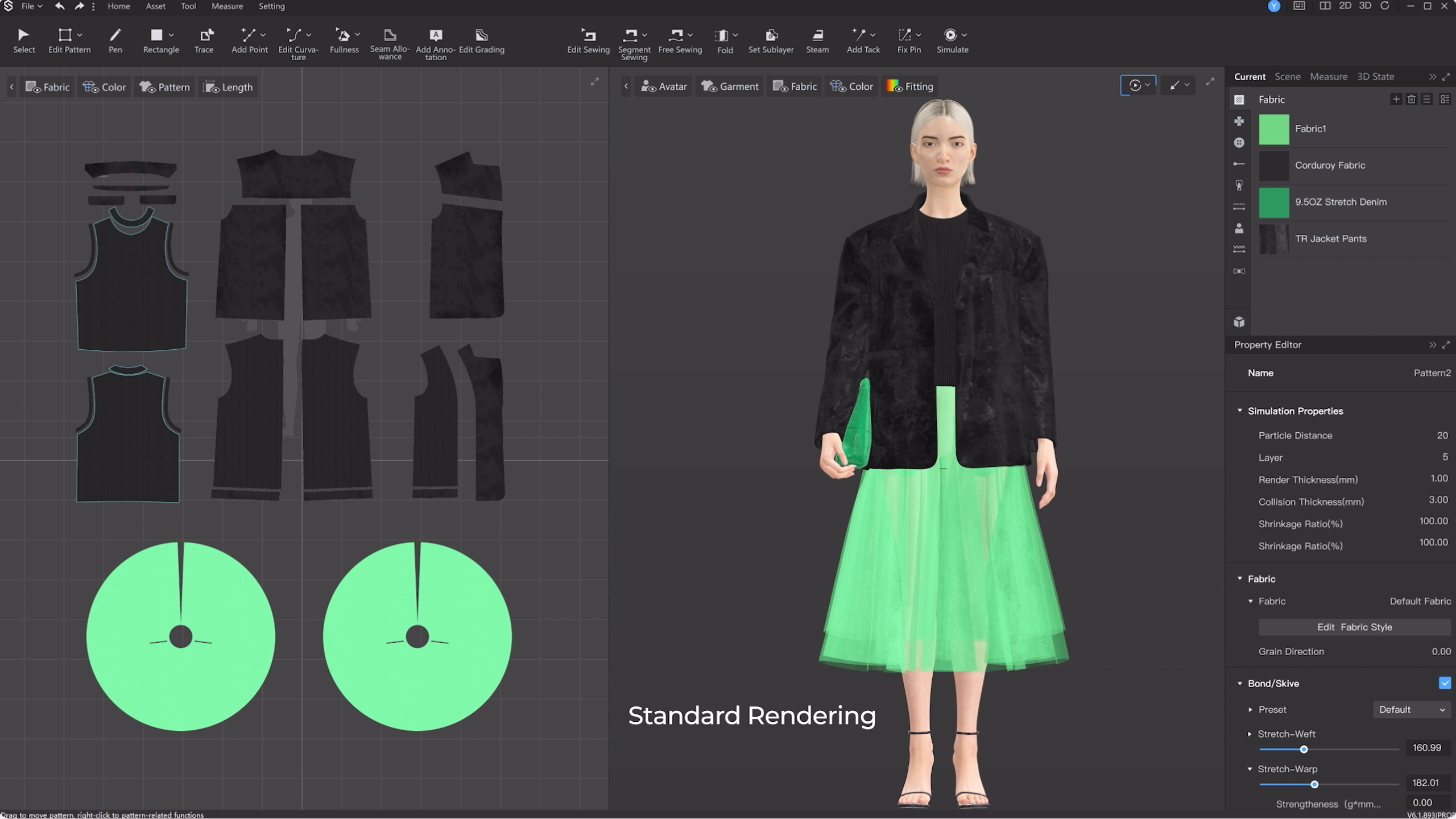

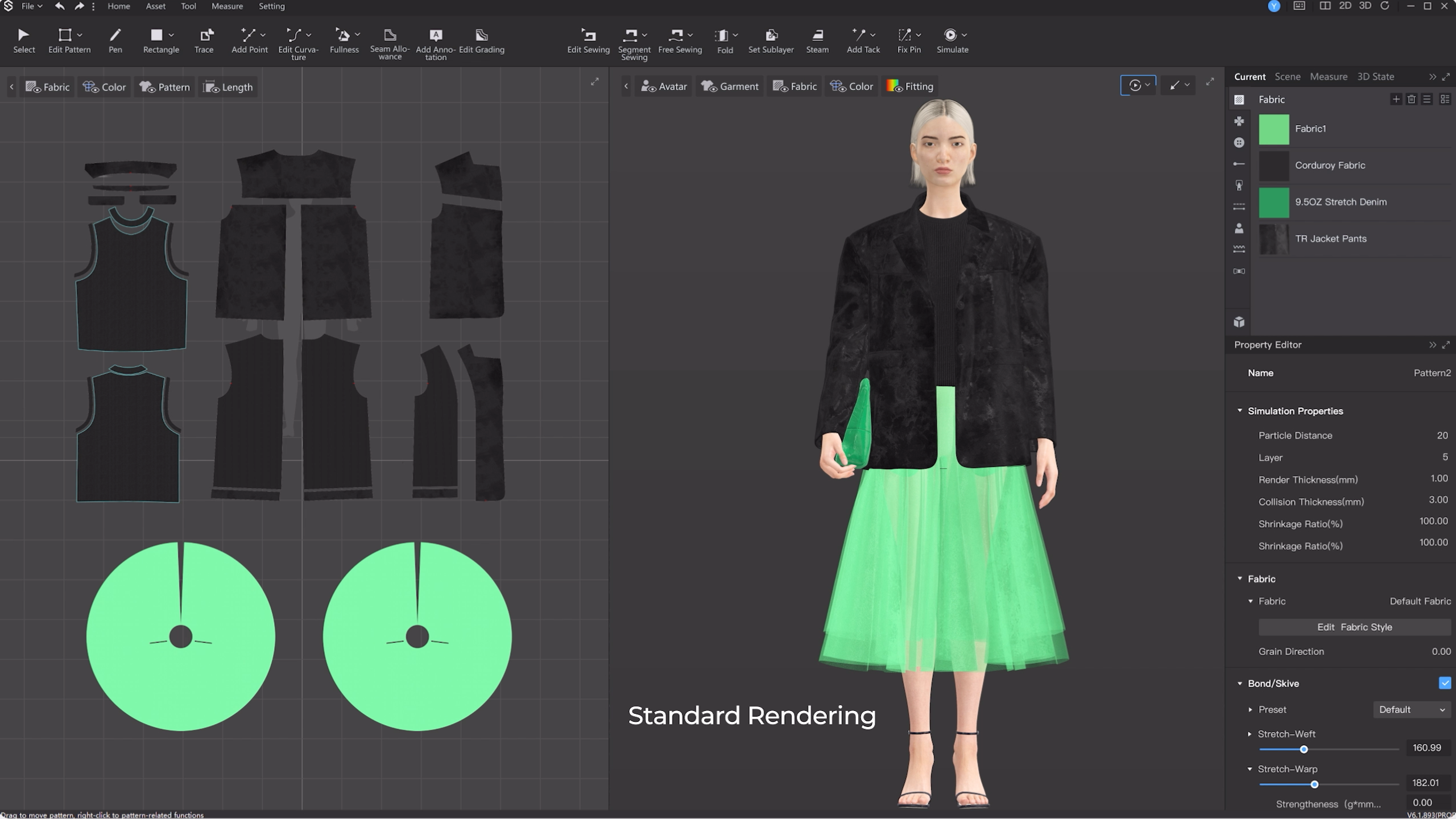

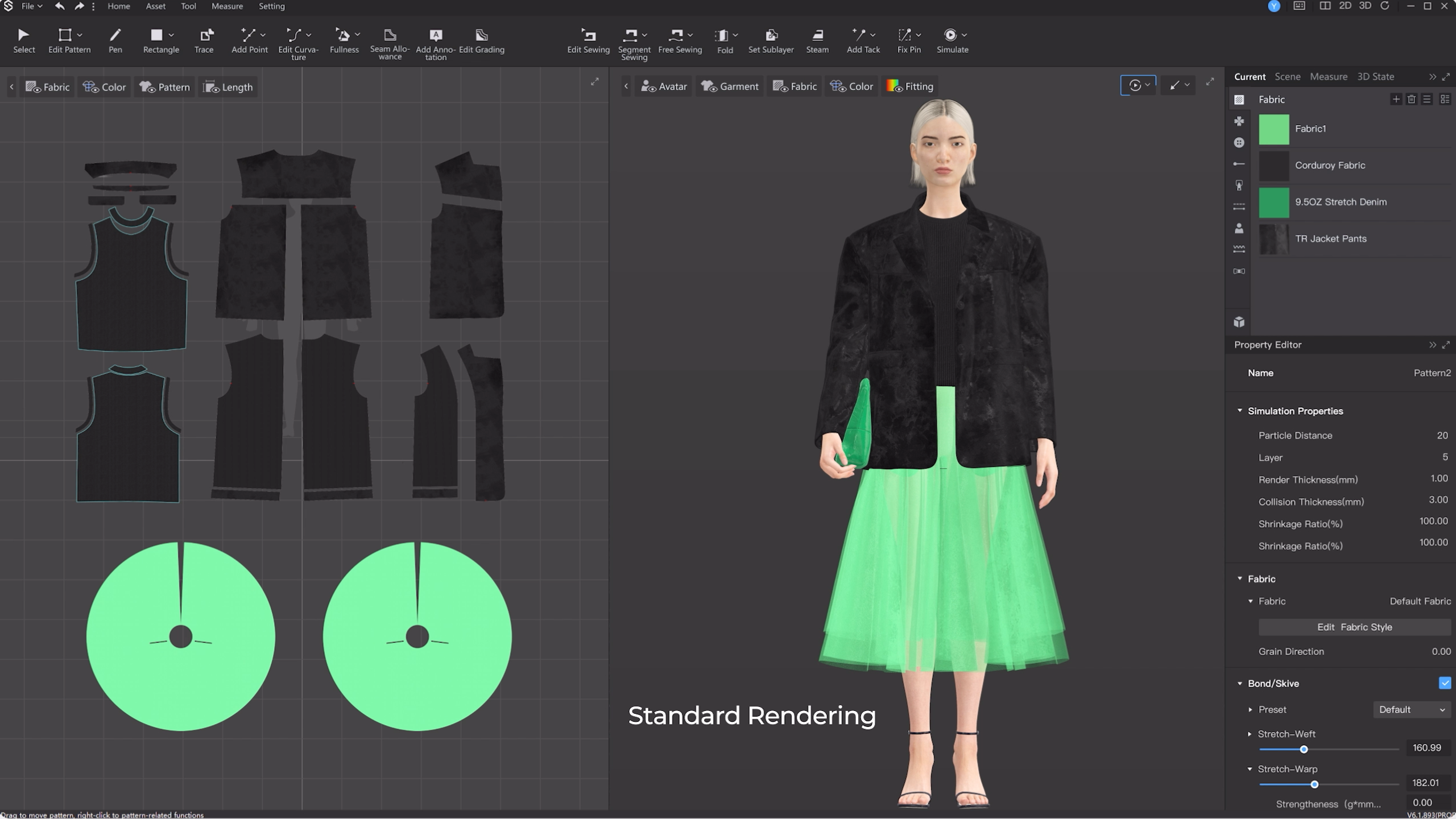

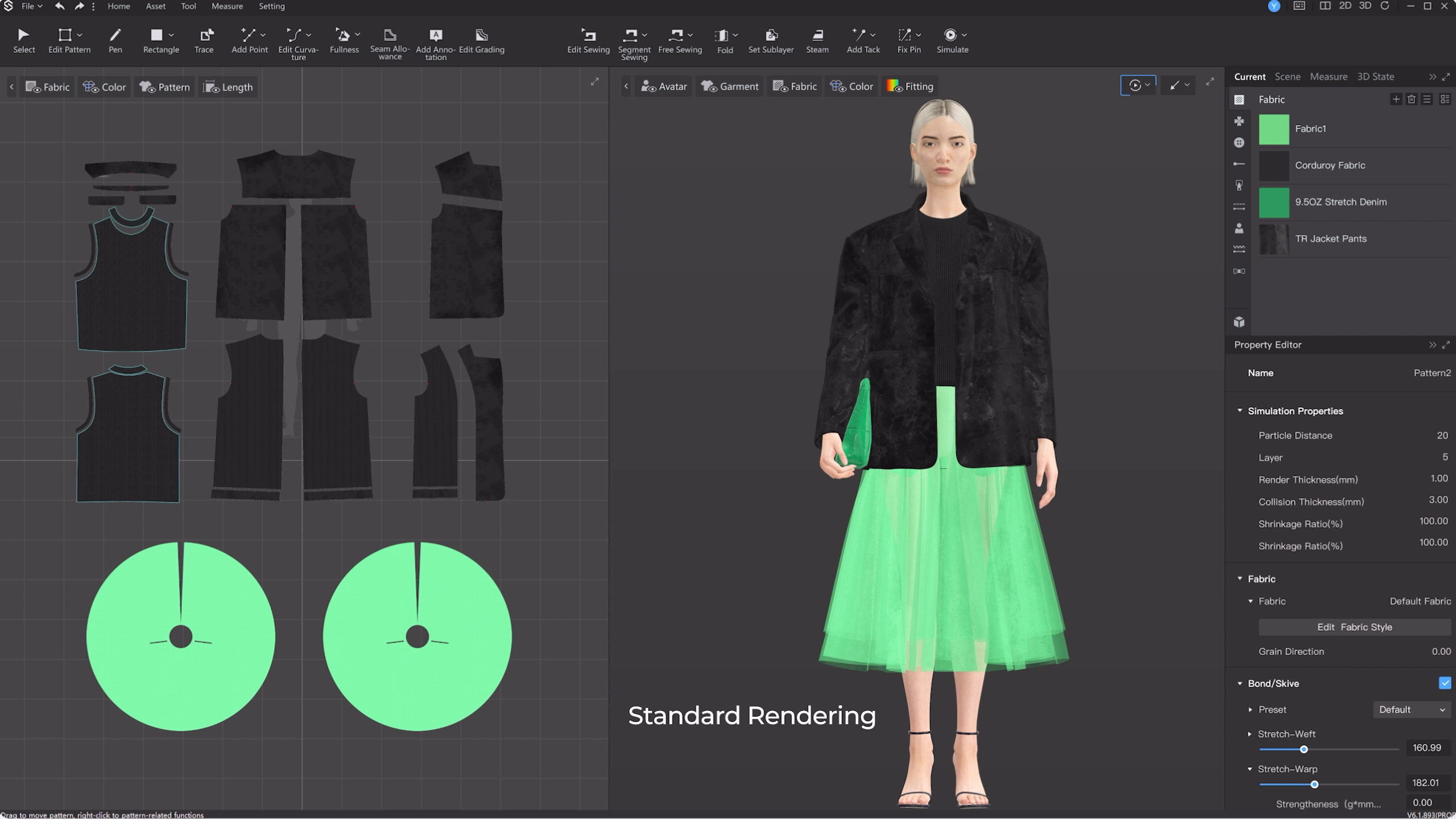

Virtual Prototyping with AI

One of the most exciting applications of Artificial Intelligence in fashion is virtual prototyping. Platforms like Style3D are leveraging AI to create hyper-realistic 3D models of garments. These virtual prototypes eliminate the need for physical samples, saving time, resources, and reducing waste. Designers can now experiment with different fabrics, colors, and patterns in a virtual environment, making the design process more sustainable and cost-effective.

Personalized Shopping Experiences

AI is also transforming the way consumers shop for fashion. By analyzing customer data, Artificial Intelligence can provide personalized recommendations, ensuring that shoppers find exactly what they’re looking for. Virtual fitting rooms powered by AI allow customers to try on clothes virtually, reducing the likelihood of returns and enhancing the overall shopping experience.

The Role of AI in Sustainability

Sustainability is a growing concern in the fashion industry, and AI is playing a crucial role in addressing it. By optimizing supply chains and reducing waste, Artificial Intelligence is helping brands become more environmentally friendly. AI-driven analytics can predict demand more accurately, preventing overproduction and minimizing excess inventory.

Conclusion

The integration of Artificial Intelligence into the fashion industry is not just a trend; it’s a revolution. From design to retail, AI is enabling brands to innovate, reduce costs, and meet the demands of a rapidly changing market. As technology continues to evolve, the possibilities for AI in fashion are endless, promising a future that is both stylish and sustainable.

Keyword: 3d clothes designer